Ine.Chidule

Coil ya LV imagwiritsa ntchito makulidwe osiyanasiyana amkuwa kapena zojambulazo za aluminiyamu ngati kondakitala, zida zamtundu wamitundu yotalikirapo ngati kutchinjiriza kosanjikiza, kutsekeka kwathunthu pamakina amtundu wa zojambulazo, kupanga koyilo.

Zipangizozi zitha kugwiritsidwanso ntchito pakupanga koyilo kofananira kwamakampani amagetsi.

Makinawa amatengera njira yowongolera ya PLC yokhala ndi mawonekedwe apamwamba amadzimadzi.

Ⅱ.Mapangidwe ndi Ntchito ya Zida

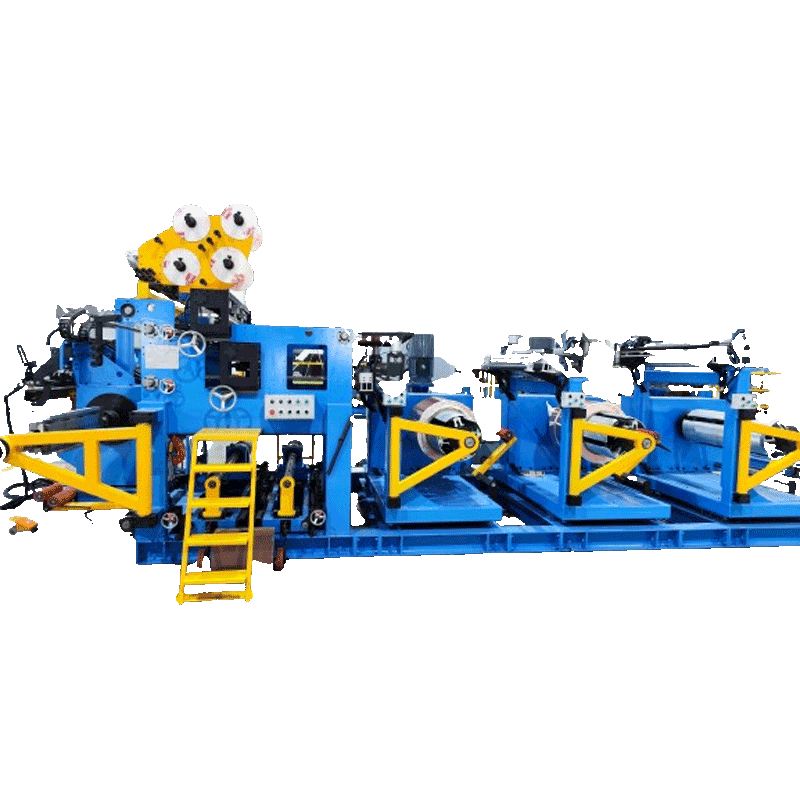

BR/III-1100 Makina Atatu Osanjikiza Ojambula Pansi akuphatikizapo

1) Foil de-coiling device 2) Chida chokhomerera 3) Chida chotchingira chosanjikiza

4) zigawo zikuluzikulu chimango 5) kuwotcherera chipangizo 6) Deburring ndi kuyeretsa chipangizo

7) Kudula chipangizo 8) Mapeto kutchinjiriza uncoiling chipangizo etc

III. Main Technical Parameters

| Sr# | ITEM | MFUNDO |

| 1 | Kolo | Mtundu wokonza |

| 1.1 | Kutalika kwa axial | 250-1100 mm |

| 1.2 | Kutalika kwa Axial (Phatikizanipo kutsogolera) | 400 ~ 1760 mm (ndi lead RH 16 inchi, LH 10inch) |

| 1.3 | M'mimba mwake (Max) | Φ1000 |

| 1.4 | Fomu ya coil | Kulemera kozungulira/cylindrical/rectangular/coil ≤2000KG |

| 1.5 | Kutalika kwapakati | 850 mm |

| 2 | Zinthu za Coil | Chojambula chamkuwa, chojambula cha aluminium |

| 2.1 | M'lifupi | 250-1100 mm |

| 2.2 | Makulidwe (Max) (Kuchuluka konse) | Zojambula zamkuwa: 0.3 ~ 2.5mm Aluminium zojambulazo: 0.4 ~ 3mm |

| 2.3 | Coil m'mimba mwake | Φ400-500mm |

| 2.4 | Koyilo yakunja (Max) | φ1000 mm |

| De-coiler | Ma seti atatu odziyimira pawokha |

| 3.1 | Kutalika kwa silinda yonyamula | 1150 mm |

| 3.2 | Kukula kwamitundu yosiyanasiyana ya silinda | Φ380~φ520 |

| 3.3 | Mphamvu yonyamula (Max) | 2000KG |

| 3.4 | Mphamvu yowonjezera (Zamagetsi) | 0~15000N Mphamvu Yokulitsa yosasinthika |

| 3.5 | Njira yowongolera | Pamanja/Automatic |

| Makina osindikizira |

|

| 4.1 | Liwiro lozungulira | 0-20 rpm |

| 4.2 | Torque yogwira ntchito (Max) | ≥ 8000N·M |

| 4.3 | Mphamvu yamamphepo | 20-30 kW |

| 4.4 | Njira yowongolera liwiro | pafupipafupi kutembenuka stepless liwiro lamulo |

| 4.5 | Mphepo yokhotakhota | 50 * 90 mm |

| 5 | Chowotcherera chipangizo |

|

| 5.1 | Welding mode | TIG |

| 5.2 | Kuyendetsa bar kuwotcherera makulidwe | ≤ 20 mm |

| 5.3 | Kuwotcherera liwiro | Kuwongolera liwiro 0~1m/mphindi Kuwongolera liwiro lopanda sitepe |

| 6 | Kudula chipangizo |

|

| 6.1 | Kudula mawonekedwe | Lead Screw Cutting Disc |

| 6.2 | Kudula liwiro | 1.5m / mphindi |

| 6.3 | Kudula kutalika | 1150 mm |

| 7. | Layer insulatingmasulanichipangizo | |

| 7.1 | Layer insulation anaika shaft | 2 seti |

| 7.2 | wosanjikiza kutchinjiriza awiri awiri akunja | ≤φ400 mm |

| 7.3 | wosanjikiza kutchinjiriza m'mimba mwake | ku 76 mm |

| 7.4 | Layer insulation roll wide | 250-1150 mm |

| 7.5 | De-coil shaft tension njira | Mtundu wa pneumatic |

| 8. | TheTSIRIZAinsulation uncoiling chipangizo |

|

| 8.1 | Kuchuluka | Kumanzere ndi kumanja ma seti 4 aliwonse |

| 8.2 | Mapeto kutchinjiriza kunja awiri | ≤φ350 mm |

| 8.3 | Kumapeto kutchinjiriza m'mimba mwake | Φ56 mm |

| 8.4 | Kumapeto kutchinjiriza m'lifupi | 10-100 mm |

| 9 . | Rchipangizo chopangira (chojambula chojambula) | Ineodziimira 3 seti |

| 9.1 | Kukonza mode | Photoelectric system |

| 9.2 | Kukonza molondola | Mwachisawawa ± 0 .4 mamilimita 20 zigawo koyilo ± 1mm |

| 10. | Njira yoyendetsera magetsi | PLC automatic control mode |

| 10.1 | Nambala ya digito | 4-digital (0–9999.9)) Kuwerengera kulondola 0.1 kutembenuka |

| 10.2 | Ntchito mawonekedwe | Chojambula chojambula chamtundu |

| 11. | Zina |

|

| 11.1 | Layer insulation kudula chipangizo | Kusintha awiri seti |

| 11.2 | Zojambulajambula zakuthupi m'mphepete deburring chipangizo | Kukonzekera ma seti atatu |

| 11.3 | Chida chotsuka zakuthupi | Kukonzekera ma seti atatu |

| 11.4 | Tanki yamadzi ozizira yowotcherera | kasinthidwe |

| 11.5 | Magetsi | 3-PH,380V/50HZ (Ikhoza makonda) |

+8613505407298

+8613505407298 trihope@aliyun.com

trihope@aliyun.com